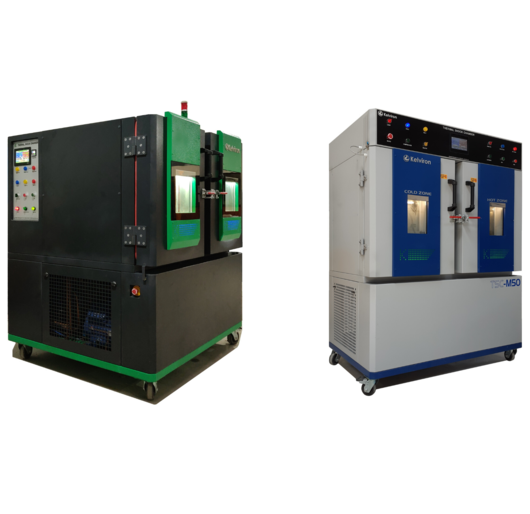

Thermal shock chamber Manufacturers & Makers in India

Thermal shock chamber is manufactured by Kelviron in compliance with MIL-STD 202,MIL-STD 810F MIL-STD 883-METHOD 1011,JE SD22-A104, GB/T 2443.1-2001 Test A: Low temp. Test, GB/T 2443.2-2001 Test B: Low temp. Test, GB/T 2443.22-2002 Test N: Low temperature test, GJB 150.3-1986 High temperature. Test, GJB 150.4-1986 Low temperature test. The thermal shock chamber has two zones namely the hot zone and the cold zone. The specimen is kept on the test basket, which is transferred between the hot & cold zones through a motorized system connected by a screw rod. It is primarily used to study the impact of the rapid change of temperature on the specimen. In real world scenarios, such rapid change in temperature causes cracking of the material, the mechanical failures and permanent change in electrical performance. It is therefore important to study and analyze such failures to design a better product in order to withstand such changing environmental conditions. Thermal shock chamber has recently undergone a series of technology upgrades to reduce the overall test time and to shorten the temperature recovery time while maintaining high uniformity. The result thus obtained shows consistent accuracy in temperature recovery and uniformity across multiple test cycles thereby improving the test reproducibility and reliability characteristics of the chamber. Inside the chamber, the hot and cold zones are sealed with specially designed gaskets to minimize leakage between the two zones. The Specially designed test basket of low thermal mass with a powerful temperature-conditioning unit enables the chamber to achieve faster recovery rates. Horizontal or vertical models consisting of cold and hot zones with product carrier basket of sizes 50, 100, 150, 300, 600 and 900 litres which transfers the specimen under test between cold and hot zones using electro pneumatic/motorized basket movement.

Thermal Shock Chamber Manufacturers Human Control Interface system

Kelviron uses colour touch programmer with built- in web server that allows remote monitoring and operation of your chamber from any Internet connected PC or smart phone. Communication ports viz., RS-232, RS-485, USB, Ethernet and USB host port. Direct real time trend capture and storage provision on the controller. This interface program has 3 user programmable soft keys with LED indication for pre-assigned functions. Graphical programming for faster programming and program view is available

Thermal shock chamber suppliers and manual system

Eurotherm (UK make) Programmable microprocessor PID controller for temperature withdigital display powerful PID, no of programs & segments each could be stored in ramp &soak period settable in hours & minutes. No of loops provided for re-appears the program. Control readout of actual and set-point values & calibration capability for actual and set values. PC communication with user friendly software.