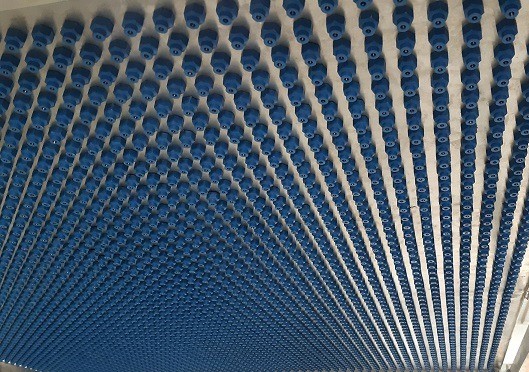

Rain Test Chamber (IPX)

- Size of the chamber: customized.

- Test Standards: Test for ingress protection against water. Standard ISO20653 & IEC-60529

- Test Water Temperature: ambient to 80°C ±5°C

- Spray Pressure: 8Mpa ~ 10Mpa (adjustable)

- Spray Flow: 14L/min ~ 16L/min (change according to pressure) or customized.

- Nozzle Number: 4 Nos (0°,30°,60°,90°,)

- Nozzle Size: As per IPX9 design &standards.

- Nozzle rotating speed: 23 RPM

- Spray Distance: 100 -150mm (adjustable)

- Nozzle Spay Time: Can be set through timer

- Spray Sequence: Can be programmable through HMI

Rain Test Chamber Manufacturers | IP X1 & X2 Manufacturers

The test equipment for IP X1 & X2 will be designed to produce a uniform flow of water drops falling vertically from a height of 200 mm above the top of the test specimen over the whole area with a water flow rate of 1 ± 0.5 mm/min and 3 ± 0.5 mm/min. The set-up will basically consist of a drip box mounted on top of a support stand with flow control and shut off valve, water pump, piping and any connecting hose. The support stand will be fabricated out of stainless steel (AISI-304 Grade) with adequate strength and rigidity. All the joints and corners will be made with high quality TIG welding and buffing. Lockable castor wheels will be provided for easy mobility. The design of the stand will be suitable to place a turn-table carrying the test specimen below the drip box. Drip tank will be fabricated out of stainless steel (AISI-304 Grade, Min.) with removable nozzles. The design of the drip box will provide easy access to the top for maintenance and cleaning. Provisions will be made for adjusting water flow rate of 1 ± 0.5 mm/min and 3 ± 0.5 mm/min through a digital flow meter and Control valve. The water pump used to fill the drip tank will be of reputed make and the water level in the drip tank will be maintained through a water level control switch automatically. Water level indication will be provided for the drip tank. Drain line with valve and overflow provision made to re-collect the water to main tank. The size of the drip tank will be 600mm X 600mm or customized to provide a minimum exposure area of 600mm X 600mm and will be mounted on the support stand at a height of approximately 2.0 m from the floor level.The pipelines used to connect the various parts of the apparatus will have adequate strength and will be durable and free from rusting.

DETAILED TECHNICAL SPECIFICATIONS OF IP X3 & IPX4The radius of the semi-circular tube will be 600mm or customized. The tube will be provided with spray holes of 0.4mm dia. for every 50mm over an arc of 60⁰ distances so that jets of water are directed towards the centre of the circle and the water pressure at the inlet of the apparatus will be approximately 80kN/m2. Provision will also be made to adjust the total flow rate equal to 0.07 l/min ± 5% per hole multiplied by number of holes.For IPX3, the tube will be caused to oscillate through an angle of 120°, 60° on either side of the vertical, the time for one complete oscillation (2 × 120°) being about 4s. For IPX4, the tube will be caused to oscillate through an angle of almost 350°, 180° on either side of the vertical, the time for one complete oscillation (2 × 350°) being about 12 seconds. For oscillation cycles automation integrated with HMI and PLC. Can be programmed the cycles and degree angle. After a period of 10 min, the test specimen will be switched off and allowed to cool naturally whilst the water spray is continued for a further 10 min. The set-up will basically consist of semi-circular spray tube supported on electro motor carriers with built-in oscillating mechanism at both ends with fully automated features like inline pressure monitoring, automatic rotating table height adjustment, 360° clockwise and anticlockwise rotations with touch screen control & monitoring. The semi-circular spray tube and the support carriers will be fabricated out of stainless steel (AISI-304 Grade, Min.) with adequate strength and rigidity. All the joints and corners will be made with high quality TIG welding and buffing. Lockable castor wheels will be provided for easy mobility. The design of the equipment will be suitable to place a rotating table carrying the test specimen at the centre point of the semicircle defined by the oscillating tube. Oscillating tube will have fixed angle limit as specified above for rotation. It will be coupled with geared motor in line with rotary joint to operate close to 360⁰. Provision will be made to automatically stop tube rotation and water flow at the precise test time. Manual mode also provided for flexibility of operation.

DETAILED TECHNICAL SPECIFICATIONS OF IPX5 & IPX6The apparatus for IP X5 & X6 will be designed and constructed to subject to specimen, to a water jet for 15 min from all directions by means of a hose having a nozzle with the shape and dimensions Provisions will be made to adjust the water pressure at the nozzle to achieve a water delivery rate of 12.5 l/min ± 5 percent (approximately 30 kN/m2) for IPX5 and 100 l/min ± 5 percent (approximately 100 kN/m2) for IPX6 The nozzles will be made out of stainless steel (AISI-304 Grade, Min.). The diameter of nozzle will be 6.3mm for IPX5 and 12.5mm for IPX6 as specified above. Nozzles will be held 3m away from the luminaries. The nozzles will be suitably placed on a height adjustable stand-alone tripod stand made of stainless steel with a pressure gauge, ball valve and connecting flexible hose of adequate length with flow meter to monitor flow rate.The electric pump used to feed water to the nozzles will be of reputed make having adequate capacity to obtain the required rate

Control Instrumentation Rain Test Chamber -

A control panel consisting of required instruments and controls will be provided for ease of operation. Mains / MCB on-off switch with Phase indicators. Outputs indicators for functional status. Single phase, phase reversal, under voltage and over voltage protection for main input power. Protection for water pump against over load. The IP Test chamber will be capable of operating on single phase 240V ± 10% or 3 Phase 415V ± 10%. The set-up will basically consist of a drip box mounted on top of a support stand with flow control and shut off valve, water pump, piping and any connecting hose. The support stand will be fabricated out of stainless steel (AISI-304 Grade) with adequate strength and rigidity. All the joints and corners will be made with high quality TIG welding and buffing. Lockable castor wheels will be provided for easy mobility. The design of the stand will be suitable to place a turn-table carrying the test specimen below the drip box. SS glycerine filled Pressure gauges and digital water flow meter. HMI touch panel for set the test cycle as per standard cycles. Automatic fault detecting system to easy & trouble-free operation. For oscillation cycles automation integrated with HMI & PLC Controller.

Control Instrumentation-single set point for manual operations or HMI Red Lion & Siemens (PLC)

Red Lion (HMI) & Siemens (PLC) or Eurotherm. This chamber comes with two controllers, it’s the choice of the customer if they want HMI or Eurotherm. For HMI 7” Red Lion high resolution TFT provided with program logic controller (Siemens). Number of programs & profile segments with ramp & soak duration provided for cyclic operation. The temperature measuring and control systems provided with PID modules. Set value & process value with graphical display on main screen.