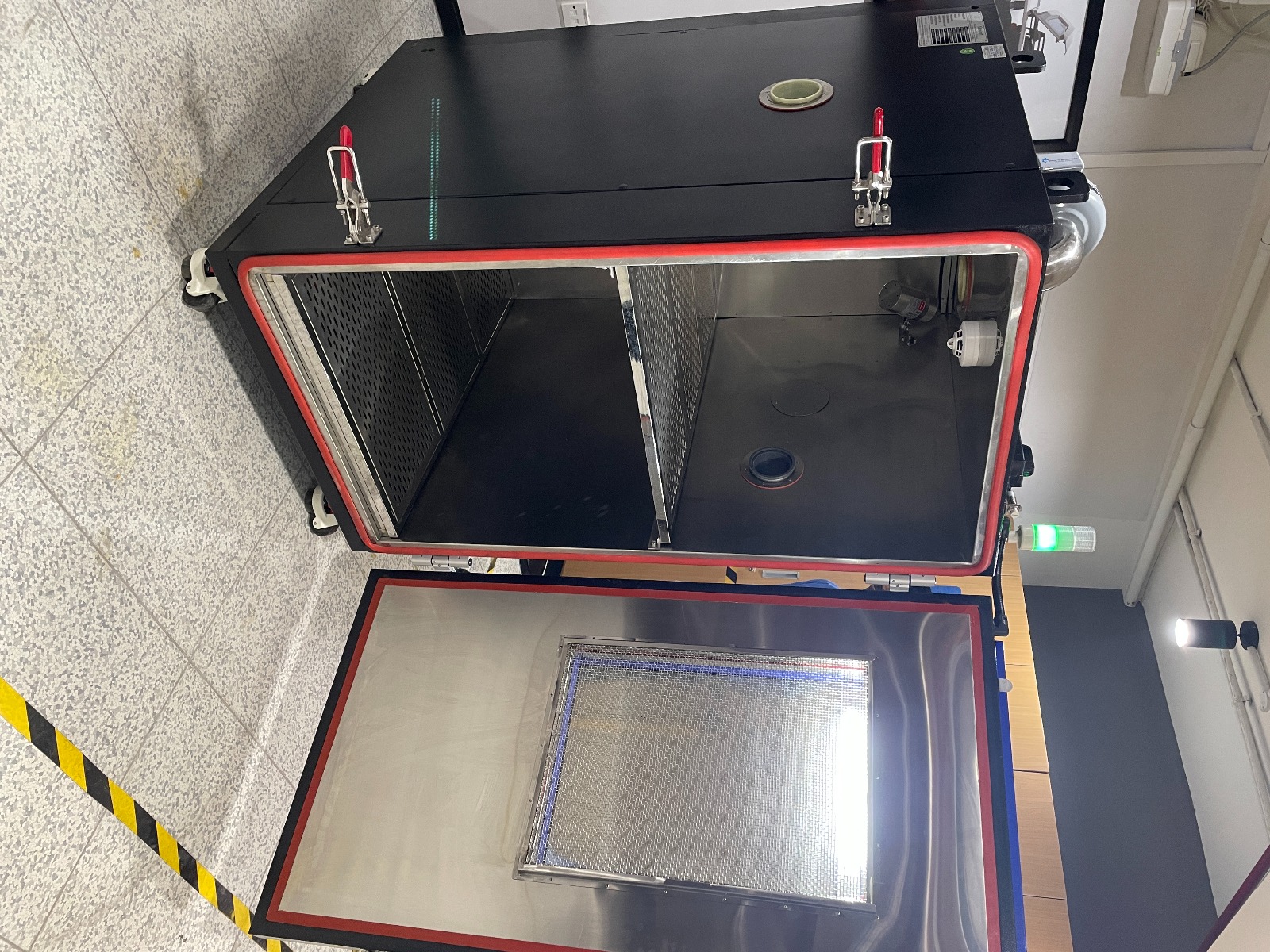

Battery Rack, Battery Holder Chamber from Kelviron - Manufacturers Exporters & Suppliers

Kelviron Technologies pioneers in manufacturing Battery Testing chambers, now this product is battery rack chamber in simple words it is called Battery Storage Chamber, Battery holder chambers. Kelviron technologies manufacture this chamber by using the latest technology. At Kelviron we manufacture this chamber according to the number of racks required by the client like 5-layer, 8-layer, 16-layer, or 24-layer. We manufacture the type of rack which the client requires like Cylindrical Cells, Flat/Pouch Cells, or Plain Shelf (can be used to organize other battery holders). The client can choose the cable length 6ft (~2m), 12ft (~3.5m), or 20ft (~6m).

The cost of batteries has dropped 80% in the last decade, making energy storage a financially viable—and advisable—solution in many applications. Energy storage works well on the current grid and with a wide variety of technologies to hedge against rising prices and volatility while supporting the proliferation of renewable. Energy storage allows power to be deployed at more strategic times, helping businesses avoid premium pricing during times of peak demand and insulating utilities against the changing energy landscape. Lithium-ion battery deployments are predicted to increase 800% from 2017 to 2022. Batteries should be stored away from sunlight, heat, and humidity. Keep the storage area ventilated and dry, and maintain a relatively steady temperature. The ideal battery storage temperature is around 59F, but most room temperatures will suffice.

Kelviron Technologies manufacturers’ best Battery rack, storage chambers. Charge-discharge tests of automotive secondary batteries have problems of being unable to perform accurate evaluation and having differences in environment temperature due to high heating of the battery during high input-output characteristic measurement and increased heat generation caused by battery degradation during long cycle and life testing. When charge-discharge testing several batteries installed in the test area at the same time, deviations in temperature uniformity and heat generation of a battery to be cause of changes in the heat history of the batteries, thereby hindering correct evaluation.

Kelviron Technologies customizes the chamber sizes according to client’s requirements. The temperature is ambient. The interior of the chamber is made of 18SWG sheet. While manufacturing this chamber Kelviron keeps in mind utmost safety, Kelviron complies with EUCAR level 6, Kelviron provides Fire detection and suppression system, they also give the best smoke detection system with alarm. The fire alarm control unit (FACU), formerly called the fire alarm control panel (FACP), contains the electronics that supervise and monitor the integrity of the wiring and components of the fire alarm system. The FACU basically serves as the brain for the alarm system. It receives signals from alarm-initiating devices, processes the signals, and produces output signals that activate audible and visual appliances. The FACU also transmits signals to an off-site monitoring station when provided. Power and fire alarm circuits are connected directly into this panel. In addition, the remote auxiliary fire control units and notification appliance panels are considered to be part of the fire alarm system and are connected and controlled. Fire detection and alarm systems are designed to receive certain types of signals from devices and perform an action based upon the type of signal received. Some signals may indicate a fire condition, while others may indicate that a device on the system needs to be serviced. The FACU should be programmed to respond to different signal types in an appropriate manner. Kelviron technologies provides N2 purging along with this chamber.N2 Purging or Nitrogen purging is an industrial process where unwanted gases and other impurities are eliminated from a manufacturing system environment using nitrogen gas. Why Is Nitrogen Used for Purging? Nitrogen is dry and non-combustible and the nitrogen displacement of combustible gases will prevent an unstable and potentially ignitable atmosphere. Purging ensures that you have control over which gases are in your gas delivery system, and therefore which gases are being exposed to internal components, sensors, or other equipment. It also helps to prevent unwanted reactions from taking place, which can greatly increase the service life of related components